When I started the assignment, I wanted to make a sound sculpture that looked nothing like a familiar instrument, but still functioned like one. Eventually I decided to go for something that made sound using wind.

I already had an idea what I wanted it to look like, even before I researched how exactly it would make the sound. I knew that when using tubes to make sound, they had a different pitch depending on the length of the tubes. It did not occur to me that I wouldn’t be able to make a sound unless I had some sort of mouth piece.

At first I imagined the sculpture to have four thick spiral tubes, polished in chrome, condensed at the bottom and sparse at the top. I imagined the tubes to have 4 mouthpieces at the bottom, which meant the person playing the instrument would either lay down, or set the instrument on an elevated platform.

However, when I started to figure out what materials to used, I realized that it would be a shame to cover up the natural copper tone.

I wasn’t a fan of the copper colour when I first bought the material, but after polishing it it started to look more like a rose gold, which I found very interesting.

The most challenging part of the assignment was probably trying to make the mouthpieces.

Making the mouthpiece was difficult because I had a lot of trouble finding the right sizes and cuts that made a good sound.

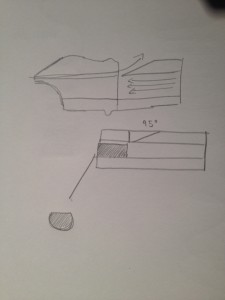

I made the mouthpiece using two different sized wooden dowels. I knew that the copper pipes were half an inch, so the inner dowel would have to be the same size to fit right into the pipe. At first I chose a slightly large diameter for the larger dowel, because I didn’t want the mouthpiece to look so chunky on the pipes.

Unfortunately after multiple failed attempts, I realized that the outer dowel was too small to drill in without cracking. Even if the wood didn’t crack, it would eventually break open when I tried to fit the smaller 1/2 inch dowel inside.

I tried patching up the cracked with plastic-like wood glue, but since the whistle was so sensitive to any air leaks, it made a very poor sound.

Finally I went out to purchase a slightly larger dowel for the outer piece. I also bought a new 1/2″ drill bit to use (which worked beautifully because the drill bit I was given at the sculpture room was extremely worn out).

The larger sized dowel was perfect, but I had some trouble cutting out the 45 degrees hole. I never realized how every single component of the mouthpiece made such a difference to the sound of it. After trying out different cuts, stains, and coats, I was finally satisfied with four uniquely made mouthpieces.

Here are some photographs of the failed mouthpieces.

(I ended up staining the mouthpieces to somewhat match the copper’s warm tone.)

When I finished my mouthpieces and tried to fit them on the copper pipes (with the end of the pipes blocked off), it didn’t make any sound at all.

I was horrified, and extremely frustrated. I wasn’t sure whether or not I should start a completely new idea. I researched a little more, and realized that the reason it didn’t make a sound was because the pipes were so long that the pressure of the air was lost.

I then had an idea and experimented, putting my mouthpiece over a water bottle and changing the volume of the water. And it worked!

Finally I filled the pipes up with water and was able to successfully make a good sound that I could even adjust using water.

When working with the pipes, I had a lot of trouble figuring out whether or not I liked the form of the pipes. I narrowed it down to three pipes instead of four. After looking at my ‘at-then’ finished product, I wasn’t satisfied with the form. It looked very busy in a disoriented way, so I took out another pipe and made it into a two pipe water whistle. After adding some extra components to the pipe to give it a more structural look, I was complete!